Kuantech focuses on providing global enterprises with top quality power conversion products. Kuantech power supplies are the ideal choice for telecommunication, audio/video, health-care and consumer electronic devices.

R&D team has profound knowledge and understanding to different electric appliance standard and requirement of different countries, and successfully drives the product innovation of world-class high-tech brand.

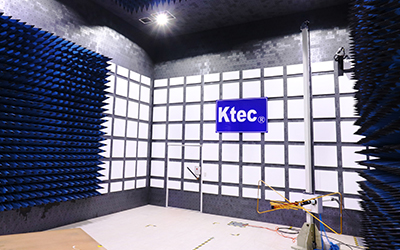

In order to satisfy the requirements of various power supply products, Ktec laboratory uses the state-of-the-art test equipment to make sure that all products of Ktec conform to the highest standards. We have the standard transport laboratories and radiation laboratories to test the products and implement anti-EMI verification.

We also have the SEKEN ESD&SURGE equipment made in Japan; the ESD verification can realize: 200V~30.5KV discharge voltage, which conforms to IEC6100-4-2 standard; thus, we can perform the contact discharge, air discharge and indirect discharge resistance verifications; we can perform the simulation to confirm whether the products can protect the whole system from being damaged after a sudden high voltage is inputted.

The cold-hot impact tester can perform the simulation to confirm the reliability of the products in operation in the environment with high temperature change; the constant temperature & humidity equipment can better the humidity resistance and high-temperature resistance performances of the products. The noise test system to reduce the noise generated during the products being in operation. The flame retardant equipment can make sure that the products conform to the flameproof safety requirements according to UL1581 and UL62. The swing equipment can perform the mechanical strength test for the cables, and realize the swing angle of 30°~180°, the frequency of 10-60 time/minute and the load of 0-1Kg. The vibration equipment can enhance the transportation protection of the products. The fluorescent tester made in Shimadzu, Japan can perform the daily ROHS and halogen-free tests for the materials; the GC-MS of PE (gas chromatograph) can perform the organic substance chemical analysis for the plastic materials in order to the materials of the products are environment-friendly.

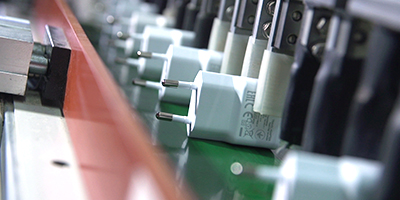

Kuantech has the comprehensive vertical integration manufacture system, able to fully coordinate to the production schedule for manufacture. Over ten thousand skilled operating personnel establish the flexible production mode for whole series power supply production operation based on the process schedule and precise automatic production equipment.

In order to guarantee the stable performance of the product, it shall pass various inspections through precision equipment before shipping, to execute the strict examination via rigorous quality control steps, and ensure the perfect quality.

Kuantech aims to assist the global enterprise development, create long-term and win-win partnerships with the customers. We are aware that trust and communication are essential for long-term partnerships.

Kuantech values the client demand to quality, listens to the client’s plan to the product, together makes the successful product, and provides the assistance in the links of whole supply chain, to help the client to success.